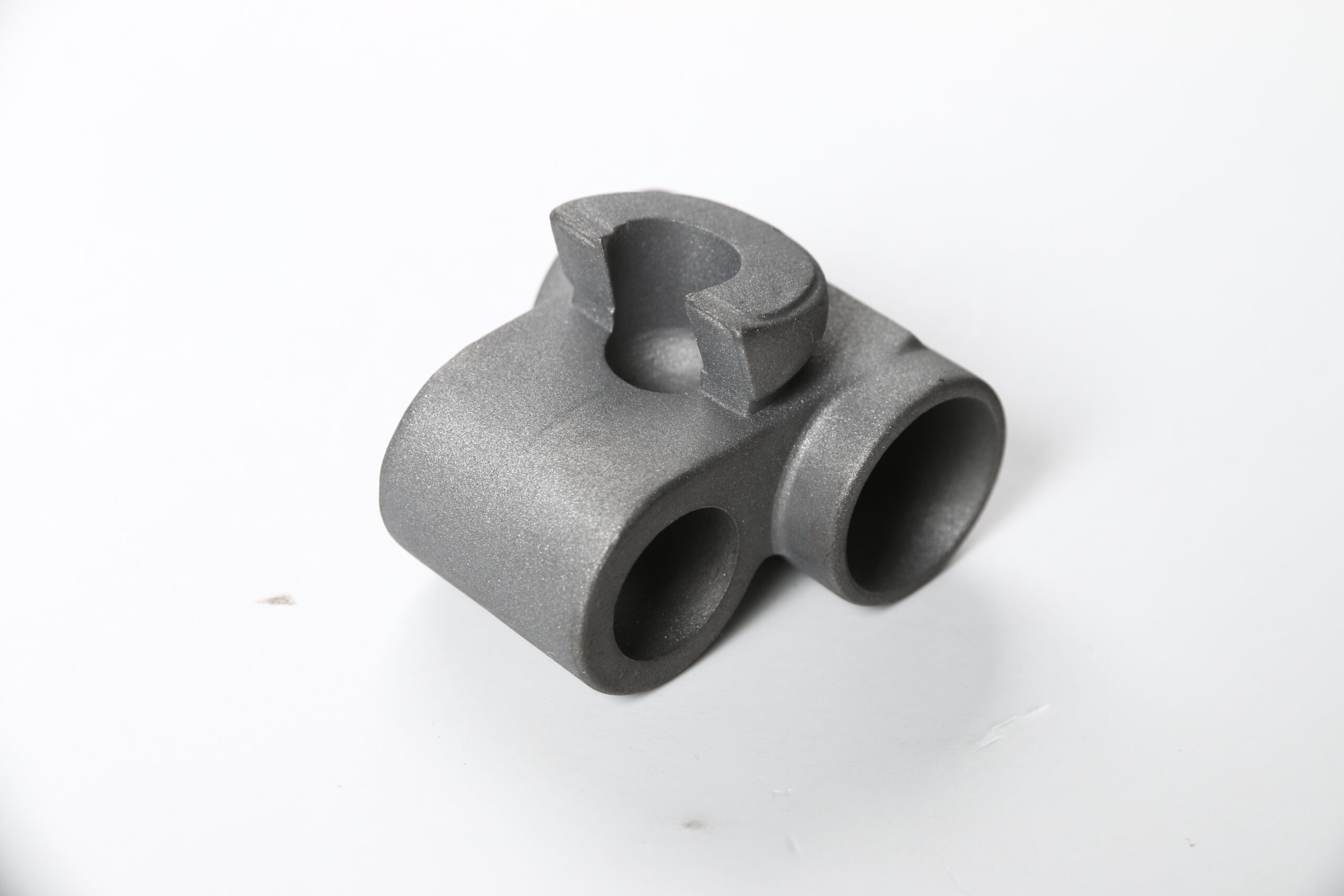

Titanium connector casting

Investment casting is also known as “lost wax casting”. Wax is injected into a metal(usually aluminum) mold to form a wax pattern. The pattern can also be produced by 3D printing from resin. This can create high-quality surface and high dimensional accuracy for complex-structured products which requires very little machining and welding.

Investment casting is also known as “lost wax casting”. Wax is injected into a metal(usually aluminum) mold to form a wax pattern. The pattern can also be produced by 3D printing from resin. Then individual wax pattern will be welded together with frame, gate cup and runners to form a tree which later coated with multiple layers of refractory slurry and sand to form a shell. The shell will be heated in the dewaxing autoclaves to remove the wax inside and then baked with high temperature. Molten titanium will then be poured into the shell inside the VAR melting furnaces, with the force of centrifugal furnace enables titanium liquid to fill the inner space of the cavity therefore gain a high-quality surface and high dimensional accuracy for complex-structured products which requires very little machining and welding.